Superconducting Dipole CICC ITER

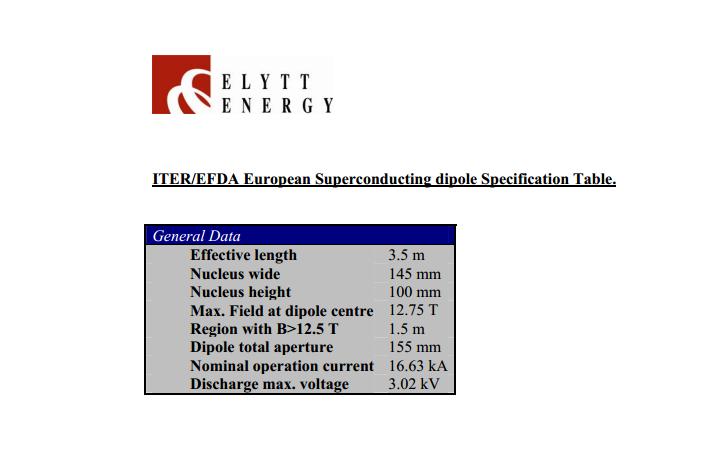

In this project ELYTT ENERGY designed a superconducting dipole for EFDA, European organization responsible for fusion developments such us ITER.

ITER is a international project for the construction of a fusion reactor. With such reactor experiments and investigations will be carried out for fusion energy obtaining. Later steps will lead to a pre-commercial fusion reactor.

In order to obtain fusion reaction between tritium and deuterium ions, the plasma containing those ions has to be heated to more than 100 millions Celsius degrees. For that, radiofrequency and neutrum injection technologies are used. One of the drawbacks of such a high temperature is that, during heating, the plasma expands and tends to contact the walls, loosing heat. To avoid this heat sink, the plasma must not touch the walls. This is done confining the plasma with high magnetic fields generated by superconducting coils.

Superconducting material looses superconducting properties under different circumstances. EFDA pretends the manufacturing of a superconducting magnet that reproduces the high magnetic field that the superconducting coils cable will have to stand.

ELYTT ENERGY has been involved in superconducting dipole design tasks.

SCOPE

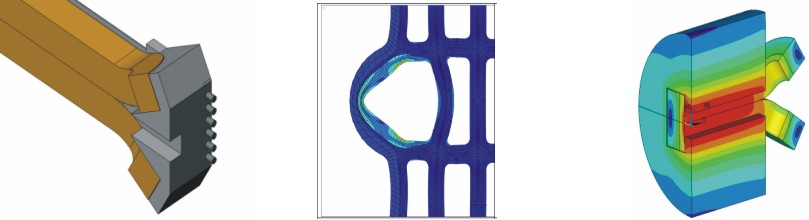

EFDA proposed different solutions for the superconducting dipole design. A first evaluation of the different solutions has been done, mainly affecting to the conductor and coil type. Two different cables are considered (Rutherford and Cable in Conduit) and two different coil types are studied (Planar racetrack and non planar racetrack). ELYTT ENERGY developed the following works:

- Non planar racetrack coil.

- 2D magnetic-static analysis: field distribution, forces/length, energy/length unit.

- 3D magnetic-static analysis: side effects, forces, energy.

- 2D stress analysis: coil central plane stress (linear elastic analysis, material properties), conduct stress (local linear elastic analysis), shear in insulation.

- 3D stress evaluation: using simplified models (beams), stresses in non planar coil region is confirmed.

- Planar racetrack with CICC (cable in conduit).

- 2D magnetic-static analysis: field distribution, forces/length, energy/length unit.

- 2D stress analysis: coil central plane stress (linear elastic analysis, material properties), conduct stress (local linear elastic analysis), shear in insulation.

- Planar racetrack with Rutherford conductor.

- 2D magnetic-static analysis: field distribution, forces/length, energy/length unit.

- 2D stress analysis: coil central plane stress (linear elastic analysis, material properties), conduct stress (local linear elastic analysis), shear in insulation.